Technologies

YOUR PARTNER ON THE ROAD TO SUCCESS

KMF is a leading, globally active company in plant and mechanical engineering that delivers exceptional technologies for extraordinary success.

With our expertise in technology, engineering, component manufacturing and service, we offer turnkey or partial systems for various applications worldwide. We are convinced that our competence and experience enable us to offer our customers the best possible solutions. KMF's leading position in international competition is based on an extensive portfolio of innovative processes and services that is continuously being expanded and developed.

We attach great importance to friendly and competent cooperation with our customers. We bring our extensive know-how and many years of experience to the overall process in order to develop and implement optimal solutions. We support our customers with our specialist knowledge and expertise.

Our commitment to continuous improvement and best-possible results is firmly anchored in our corporate culture. We are proud to offer our customers high-quality products and services and to accompany them, as their steadfast partner, on their road to success.

The activities of KMF are divided into three business areas according to our customer and application spectrum.

INDUSTRIAL

TECHNOLOGIES

GRINDING

TECHNOLOGIES

ALUMINIUM

TECHNOLOGIES

INDUSTRIAL TECHNOLOGIES

INNOVATIVE, CUSTOM SOLUTIONS

We are proud to be our customers' exclusive partner for mineral-filler processing. Our range of services includes the development, construction and maintenance of special machines such as high-speed classifiers, centrifuges, dewatering units and thermal processing systems for high-temperature melting processes.

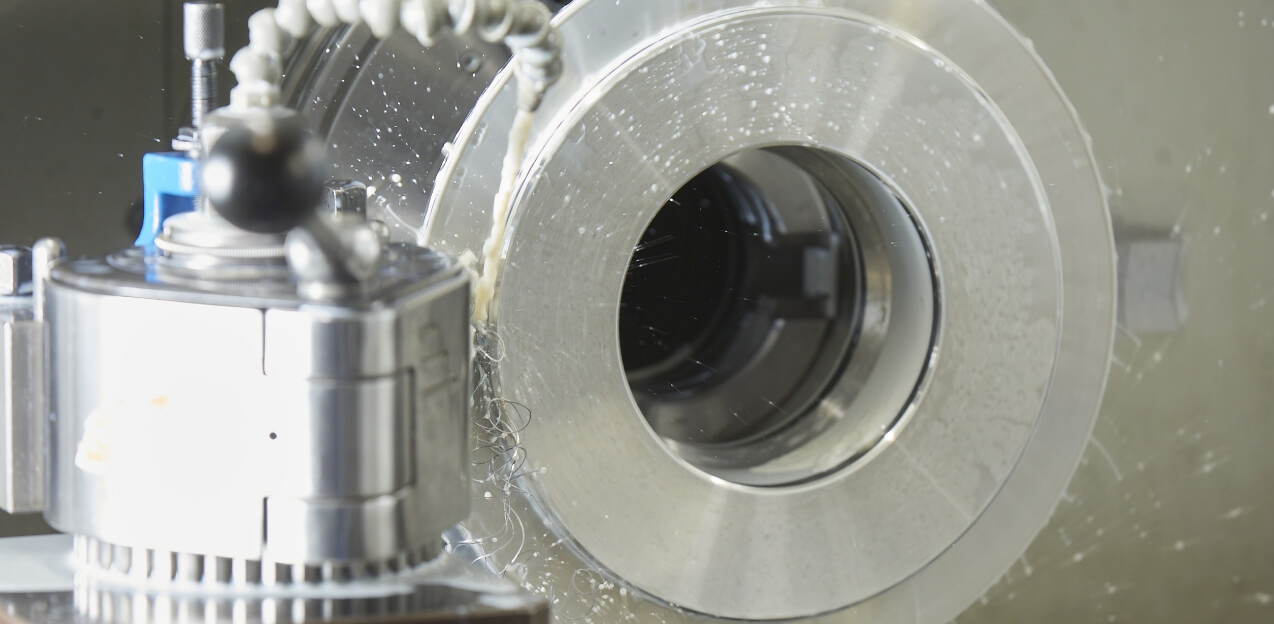

GRINDING TECHNOLOGIES

SERVICES AT THE HIGHEST STANDARDS AND REQUIREMENTS

KMF has made a significant contribution to making this outstanding grinding technology available to the mineral processing industry. Through continuous innovation and first-class service, KMF supports its customers in meeting the demanding requirements of today's mineral processing industry and adapting to changing market conditions.

ALUMINIUM TECHNOLOGIES

NEW POSSIBILITIES IN RECYCLING

Recasting aluminium requires 10 to 15 times less energy than primary production from bauxite. Recycling aluminium significantly reduces CO2 emissions. By recycling 2 million tons of secondary aluminium, around 30 million tons of CO2 could be saved annually, with 4.5 million tons being saved through sufficient slag cooling alone.

QUALITY & CERTIFICATIONS

ADDED VALUE AND SAFETY FOR OUR CUSTOMERS

KMF attaches great importance to a certified and regularly reviewed quality management system that supports all areas of our company. This system enables us not only to maintain the high performance standard, but also to continuously improve it for the benefit of our customers.

Our application-oriented product philosophy is reflected in tangible, pragmatic advantages for our customers. Our products and systems are characterised by simplicity, speed and, above all, cost-effectiveness. Our goal is to offer solutions that meet the needs and requirements of our customers in the best possible way.

By integrating all areas of the company into our quality management system, we ensure that every step in the production process meets the highest standards. This enables us to deliver products of outstanding quality that offer our customers real added value.

Certificates and audits prove our competence and quality and give our customers the security of receiving high-quality and reliable products that meet the highest of demands.

ISO 9001:2015

This certificate confirms that our quality management system complies with the ISO 9001 international standard

EN3834-2

This certificate of suitability confirms our welding qualifications in accordance with the EN3834-2 European standard

EN1090-2 EXC 3

This certificate of suitability confirms our welding qualifications in accordance with the EN1090 European standard

EN15085-2 CL1P

This certificate confirms our ability to weld rail vehicles and rail vehicle parts